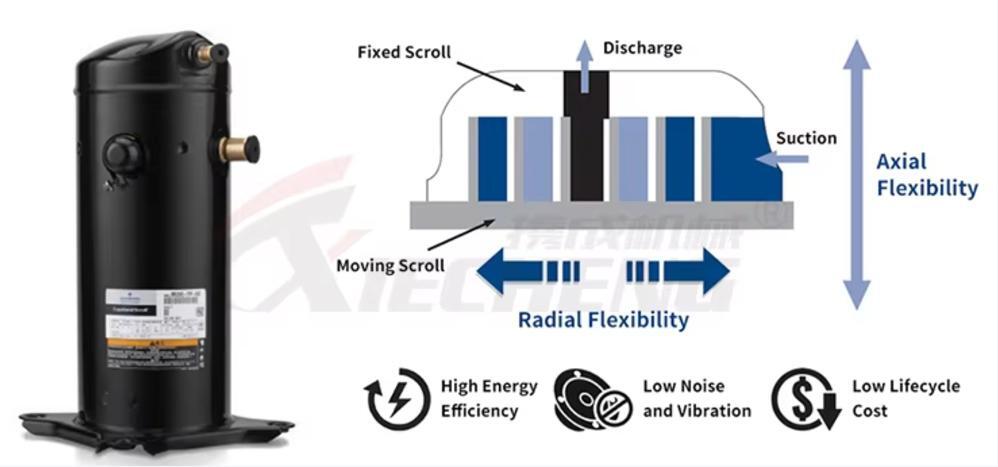

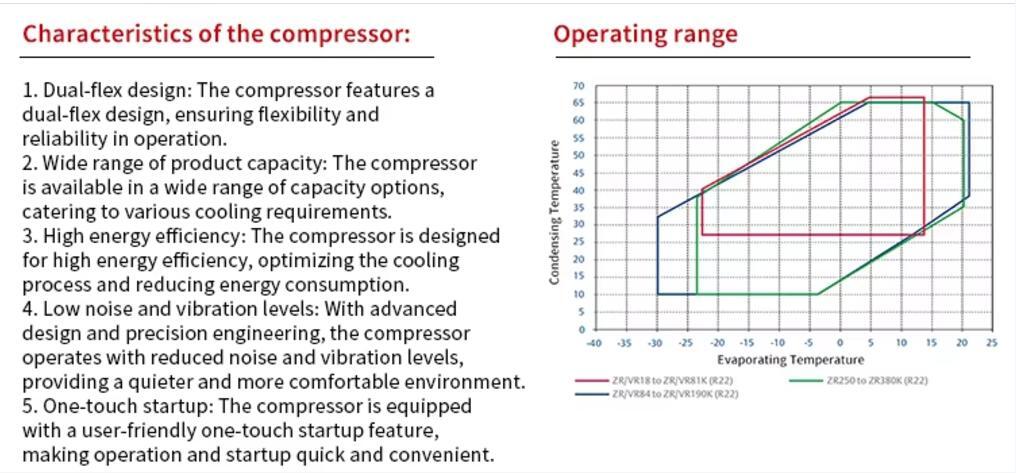

Scroll Compressor

The entire range of MORI MACHINE brand Industrial Water Cooled Chiller Cost utilizes scroll compressors. The compressor serves as the heart of the entire refrigerant cycle system. The scroll compressor adopts a dual-flex design, ensuring tight sealing between the scroll discs. This design allows the scroll discs to separate radially and axially, allowing debris or liquid to pass through without damaging the compressor. This results in increased compressor lifespan, enhanced reliability, better liquid tolerance, and improved tolerance for impurities.

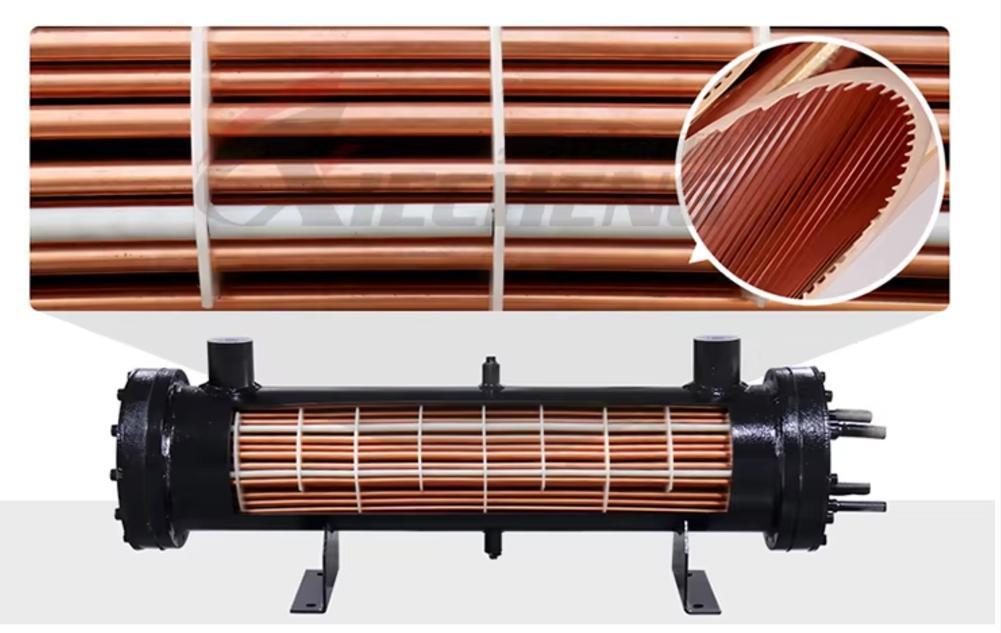

Shell and Tube Evaporator

Industrial Water Cooled Chiller Cost utilizes a shell and tube evaporator. In this system, the refrigerant evaporates inside the heat exchange tubes, while water flows on the shell side. To enhance the heat exchange efficiency, a 2mm thick baffle plate is installed on the shell side, causing the water to flow back and forth to create ice brine. Additionally, to maintain a stable operating temperature, the exterior shell of the evaporator is covered with insulation material.

For the heat exchange tubes, we employ high-efficiency seamless copper tubes. These tubes undergo a grooving process to form internal thread fins, thereby increasing the heat exchange surface area with the refrigerant. With this technology, the heat transfer area is doubled, significantly improving the heat transfer efficiency.

Shell and Tube Condenser

Industrial Water Cooled Chiller Cost utilizes a shell and tube condenser, with the internal copper tubes employing an outer thread embossing process. This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Technical Parameter | ||||

1.Model | MO-08A | MO-10A | MO-12A | MO-15A |

2.Cooling capacity | 20KW | 28.01KW | 32.4 KW | 40 KW |

17,224 Kcal/h | 24,089 Kcal/h | 27,904 Kcal/h | 34,449 Kcal/h | |

3.Temperature range | 5~25 ℃ (This is standard temperature range,If you need to customize other temp., you can consult email:morimachinery@163.com) | |||

4.Voltage | 3phase/ 380v/ 50hz (This is standard voltage,If you need to customize other voltages, you can consult email:morimachinery@163.com) | |||

5.Total power | 8KW | 9.9KW | 11.4KW | 16.65KW |

6.Compressor | Type:Hermetic Scroll Type or Piston | |||

Power:6kw | Power:7.5kw | Power:9kw | Power:13.5kw | |

Refrigerant:R407C (If you need to customize other refrigerant, you can consult email:morimachinery@163.com) | ||||

8.Condenser | Shell and tube | |||

9.Evaporator | Type:Tank + Copper Coils | |||

Inlet and outlet port:G1-1/2 ‘’ | Inlet and outlet port:G2 ‘’ | |||

10.Tank | 100Liters | 160liters | ||

11.Pump | Power: 1.2kw | Power: 1.5kw | ||

12.Size | 145x63x131cm | 175x66x142cm | ||

13.Weight | 413kg | 813kg | ||